Feature of this machine

- 1. Compact construction, high efficiency. Accurate temperature control of the shrink tunnel. Strong air-flow ensures excellent heat distribution for an even shrinking.

- 2. All kinds of films can be used on this machine, and the effect is all good. All of the machine parts adopt brand products, it ensures the quality of the machine.

- 3. The input power must bigger than the power that noted on the scutcheon, or the circuitry or the components will be burned. The machine must be connected properly, or it is a danger for the operator.

- 4. It adopts a quartz tube Far-infrared heating method while working, it can shed far-infrared continuous, the large power cooling system makes the tunnel temperature symmetrical, and it can reduce electricity consumption.

- 5. The transportation part adopts a large AC motor, it can adjust the speed successive and there is a large load ability. It can continuously work for a long time running stable and reliable.

- 6. The transportation part of the middle and large machine adopts the roller that can turn by itself while working, this makes the shrink effect of the bottom of the object better.

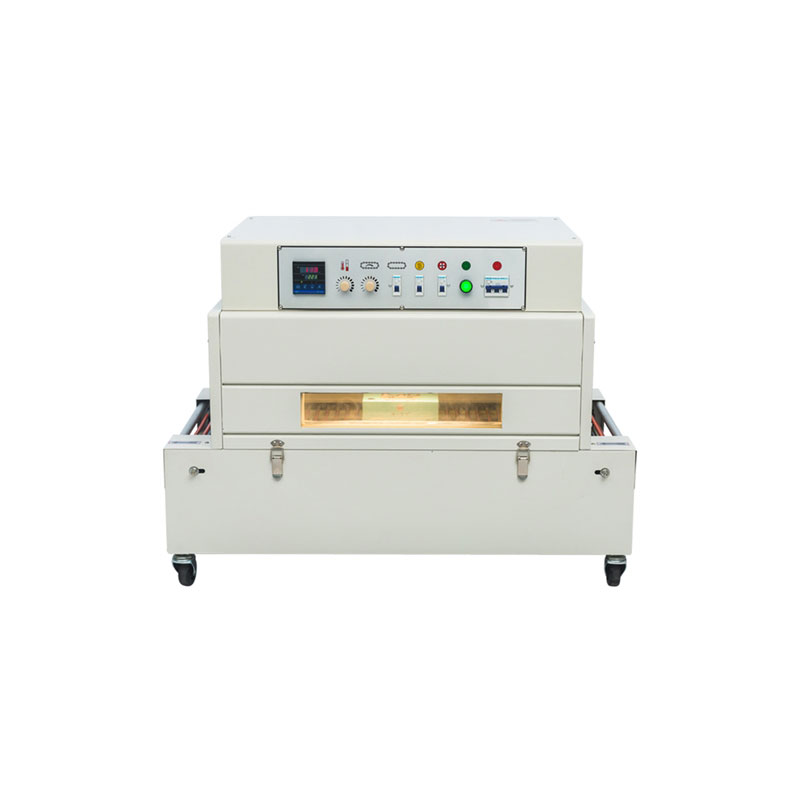

- 7. Adopting special machine structure design, it looks more beautiful and luxurious, and the maintenance becomes easy and convenient.

- 8. It adopt the special method to control the temperature, which combines the temperature meter and the solid-boost, it makes the mistake bottom out.

- 9. When it is prescribed the power is 380v three phases, it must input the zero wire, it is standard 3 phases 4 wires. or the machine can__ work normally, it is very easy to burn the components.

Specification of this machine

| Model | BS-A450 |

| Commodity | thermal shrink tunnel |

| Voltage | 220V/50-60HZ |

| Heater Power | 9 kW |

| Conveyor speed | 0-10m/min |

| Workroom size(L*W*H) | 830*450*250mm |

| Max conveyor loading | 10kg |

| Machine weight | 110kg |

| Machine size | 1200*650*1300mm |

Reviews

There are no reviews yet.